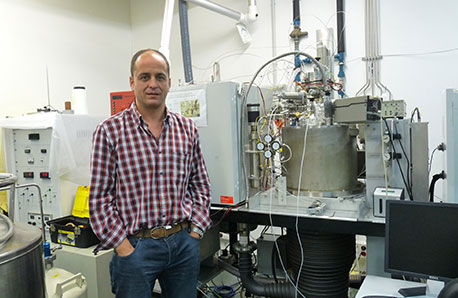

Heterogeneous Catalysis Unit

THE UNIT IN 2014

This unit provides support to the researchers of the Institute working in heterogeneous catalysis (gas phase reactions catalysed by solids). Other research lines involving solids characterization, from a chemical and a physical point of view and on-line analysis of gases can also benefit from the Unit. State-of-the-art techniques for the catalysts characterization and testing are available to carry out both conventional experiments and advanced applications that are developed in collaboration with the research groups or other research units.

In 2014, outstanding new procedures were carried out:

- Physisorption and chemisorption in an Autosorb iQ (Quantachrome). Textural characterization of industrial and new developed metallic orgranic frameworks (MOF). Chemisorption of CO2, H2 and CH4 over the same type of material.

- Online gas analysis with Omnistar (Pfeiffer) mass spectrometers in the following experiments:

- Ethane coupling to produce higher hydrocarbons.

- Electro-CO2 reduction.

- O2-TPD over polycrystalline RuO2.

- Partial oxidation of methanol to formaldehyde in a Microactivity Reference (PID Eng&Tech). Methanol, formaldehyde and byproducts are analyzed by a GC with an automatic sampling system for gases.

- Oxidation of HBr to Br2 in a TAP reactor (Mithra Technologies).

Moreover, some singular experiments were run:

- Oxygen temperature programmed reduction (TPD) over polycrystalline RuO2 in a Thermo TPDRO 1100.

- Online gas analysis by MS combined with in situ FTIR in the catalytic conversion of methanol and CO2 to dimethyl carbonate.

- Size measurement of binaphthyl functionalized ftalocyanines by DLS.

Finally, the unit staff participated actively in the following published paper: Catalysis Today, 228 (2014), 212–218. Oxidative coupling of methane — A complex surface/gas phase mechanism with strong impact on the reaction engineering. Benjamin Beck, Vinzenz Fleischer, Sebastian Arndt, Miguel González Hevia, Atsushi Urakawa, Peter Hugo, Reinhard Schomäcker.

MOST IMPORTANT EQUIPMENT

- AUTOSORB iQ®(QUANTACHROME).

- micro-Ultrapycnometer 1200e®(QUANTACHROME).

- TPDRO 1100®(Thermofisher).

- Microactivity Reference®(PID Eng&Tech).

- OMNISTAR® (Pfeiffer) and 6890N (Agilent). Two MS and a GC for the on-line analysis of gases.

- TAP-2 reactor (Mithra Technologies®).

- Nano-ZS (Malvern®).